UHB series pump is a single-stage single suction cantilever centrifugal pump, and the flow-through part is made of steel lined with UHMWPE. This material is a new generation of corrosion-resistant and wear-resistant engineering plastics for pumps in the world. Its most outstanding advantages are excellent corrosion resistance, impact resistance (especially low temperature impact resistance), creep resistance (environmental stress cracking resistance) and excellent corrosion resistance.

The remarkable features of the product are: multi-function, the pump can adapt to various working conditions, such as conveying acid, alkaline clear liquid or slurry; various corrosive slurry in smelting industry; various dilute acids in sulfuric acid industry; various sewage in environmental protection industry, etc. The pump is not only corrosion-resistant and wear-resistant, but also widely used.

The pump has been used for a long time in delivery of acid pulp and dilute acid in more than 40 large non-ferrous smelting and sulfuric acid enterprises such as Shandong Linyi Coking Plant, Jiangxi Guixi Smelter and Nanhua Group. Its corrosion resistance, wear resistance, sealing reliability and service life have been highly evaluated.

Main technical description

1. Model:UHB-ZK series

2. Features: corrosion resistance and wear resistance, one pump for multiple purposes, applicable to acid and alkali clear liquid slurry.

3.Structure:

(1) The pump body is steel lined with ultra-high molecular weight polyethylene, and the lining thickness is 8-20mm.

(2) Impellers are divided into open and closed type,which can be selected according to the medium conditions.

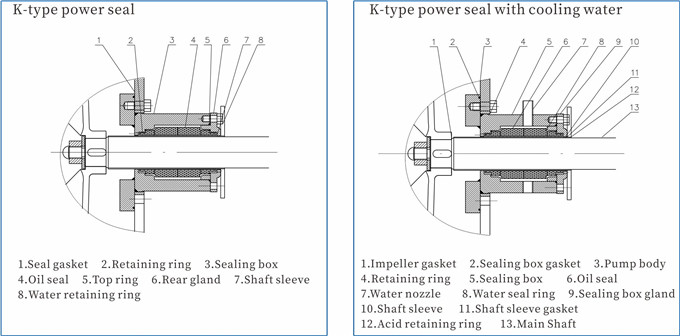

(3) Seal: K-type power seal.

4.Applicable medium: sulfuric acid with concentration below 80% and nitric acid with concentration below 50%. Hydrochloric acid and liquid alkali with various concentrations,it is applicable to both clear liquid and slurry.

5. Main technical parameters: service temperature - 20 ℃ ~ 80 ℃ (for special requirements and using modified materials, it can be increased to 105 ℃), inlet diameter Φ 32mm ~ Φ 250mm, flow 5 ~ 600m3 / h, and head within 50m.

6. Special warning: it is strictly prohibited to reverse, so as to make the impeller cap fall off. It is strictly forbidden to operate without liquid, which will damage the dynamic seal.

Extremely wide range of use

1. Phosphate sulfate industry: transportation of dilute acid, mother liquor, sewage, sea water, silicofluoric acid containing silica gel, phosphoric acid slurry and other medium.

2. Non ferrous metal smelting industry: it is especially suitable for the transportation of various kinds of acid, corrosive pulp, slurry (with filter press) electrolyte, sewage and other medium during hydrometallurgy of lead, zinc, gold, silver, copper, manganese, cobalt,rare earth,etc.

3. Chemical and other enterprises: Clear liquid or slurry of various sulfuric acid, hydrochloric acid, alkali and oil.

4. Chlor alkali industry: hydrochloric acid, liquid alkali, electrolyte, etc.

5.Water treatment industry: pure water, high-purity water, sewage (leather sewage, electroplating sewage, electronic sewage, paper sewage, textile sewage, food sewage, domestic sewage, pharmaceutical sewage, etc.).

6.Iron and steel enterprises: sulfuric acid and hydrochloric acid of pickling system, sewage with impurities.

7. Matching wet desulfurization dust remover: it can be applied to alkaline, acid and corrosive medium at the same time.

Model meaning

50 UHB - ZK - 20 - 30

50 :Head(m)

UHB:Flow(m³/h)

ZK:Z impurity mortar, K-type dynamic seal

20:UHMWPE pump code

30:Diameter of pump inlet

1、When the pump inlet diameter is ≤ 125mm, (excluding auxiliary impeller),

refer to structure drawing 1.

2、When the pump inlet diameter is more than 125mm (including auxiliary impeller),

refer to structural drawing 2.

Seal structure diagram

Description of startup, operation, maintenance,disassembling and installation procedures

1. Inspection before operationBefore the test run, the coupling or shaft shall be turned by hand to check whether the direction is correct and whether the operation is flexible. If the coupling does not move or there is abnormal sound, it shall be checked in time. During the inspection, the coupling shall be checked whether it is horizontal by hand from the outside, and the position of the lubricating oil shall be checked from the oil mirror hole on the bearing seat to see whether it is near the center line of the oil mirror (if the lubricating oil is too much,please let off some, if it is too little,please add some), and please check while turning. If the problem still exists, disassemble the pump for inspection. (please refer to the structural diagram and disassembling procedure in this manual when disassembling the pump). Clean up the foreign matters and contact our factory for solutions.

2. The procedure of startup

a. Fill the pump with liquid

b.Open the inlet valve in time (if the inlet and outlet valves are one-way check valves, no manual operation is required)

c. Power on

d. Open the outlet valve

3. Operation

In case of abnormal sound or abnormal condition such as motor heating during operation, the machine shall also be shut down for inspection. The inspection method and steps are the same as 1.

4. The procedure of stop

a. Close the outlet valve first

b. Cut off the power supply and timely close the valve at the inlet; (If the inlet valve is a one-way check valve, no manual operation is required)

5. Maintenance

a. The lubricating oil in the bearing seat shall be replaced regularly, and it shall be replaced once every six months under normal conditions.

b. In cold season, if there is ice phenomenon after the pump is stopped, the cooling water at the seal shall be connected first. If necessary,hot water can be added to defrost, and then the coupling can be turned by hand until the operation is flexible, and then the pump can be started according to the starting steps.

c. For the pump with cooling water device, the cooling water shall be connected before start-up. When the pump is in normal operation, it can continue to be connected. If the condition is not allowed, it can also be stopped. The flow and pressure of the cooling water are not required, and the tap water is OK.

d. The operation of the pump when the outlet valve is closed is called the closed pressure operation state. The closed pressure operation time of the all plastic pump or the lined plastic pump shall be shortened as much as possible.The time shall not exceed 5 minutes for normal temperature medium, and the time shall not exceed 2 minutes for high temperature medium.

e. For the pump of the split pump shell, such as the pump with an inlet of more than 150mm,the size of the sealing plastic at the split surface will change due to thermal expansion and cold contraction, the connecting bolts at the split shall be tightened before connecting the inlet pipeline to prevent the leakage of the split surface, which is particularly important for Beidou Xingfang users.

f. The pump cannot bear the weight of the inlet and outlet pipes. The shorter the inlet pipe is, the better. The vertical height from the pump outlet to the valve should be as short as possible.

g. Keep the motor free of water traces to prevent the motor from moisture.

6.Disassembling and installation procedures.

(1). Pump without auxiliary impeller(the pump inlet diameter is ≤ 125mm)

Disassembling sequence: (refer to the structure drawing in this manual)

a. Loosen the connecting bolts between the pump body 5 and the pump cover 1 and remove the pump cover

b. Loosen the impeller match cap 2 (left-hand thread) and the anti rotation nut 3 (left-hand thread), and remove the impeller 4

c. Loosen the connecting bolts between the pump body 5 and the bearing seat 10 and remove the pump body 5

d. Loosen the connecting bolts between the seal box 6 and the pump body 5 and remove the seal box 6

e. Unscrew the rear gland on the sealing box and take out the oil seal

The installation sequence is the reverse of the disassembling sequence, and it should be noted that:

a. Check the gap between the impeller and the pump body after tightening the impeller match cap. The gap is required to be about 2mm

b. After the pump cover is installed, check the gap between the pump cover and the impeller (from the outlet to the inside). The gap should be about 2mm. For the pump delivery high-temperature medium, the gap should be about 2.5mm

c. If the gap between impeller and pump body fails to meet the requirements, it can be adjusted by increasing or decreasing the gasket between impeller and shaft sleeve

d. If the gap between the pump cover and the impeller fails to meet the requirements, it can be adjusted by increasing or decreasing the gasket between the pump body and the pump cover

2. Pump with auxiliary impeller(the pump inlet diameter is >125mm)

Disassembling sequence: (refer to the structure drawing in this manual)

a. Loosen the connecting bolts between the pump body 5 and the pump cover 1 and remove the pump cover 1

b. Loosen the impeller match cap 2 (left-hand thread) and the anti rotation nut 3 (left-hand thread), and remove the impeller 4

c. Loosen the connecting bolts between the pump body 5 and the bearing seat 12, loosen the connecting bolts between the seal box 7 and the pump body, and remove the pump body 5

d. Remove the auxiliary impeller, seal box, oil seal and shaft sleeve in proper sequence

The installation sequence is the reverse of the disassembling sequence, and it should be noted that:

a. Check the gap between the impeller and the pump body, which should be about 2.5mm according to requirement, after the matching cap of the impeller and the nut behind the water retaining ring are relatively tightened

b. After the pump cover is installed, check the gap between the pump cover and the impeller (from the outlet to the inside). The gap should be about 2mm. For the pump delivery high-temperature medium, the gap should be about 2.5mm

c. If the gap between impeller and pump body fails to meet the requirements, it can be adjusted by increasing or decreasing the gasket between impeller and shaft sleeve

d. If the gap between the pump cover and the impeller fails to meet the requirements, it can be adjusted by increasing or decreasing the gasket between the pump body and the pump cover

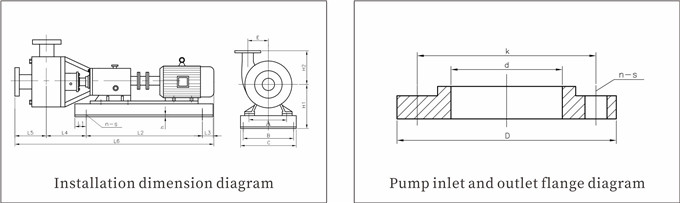

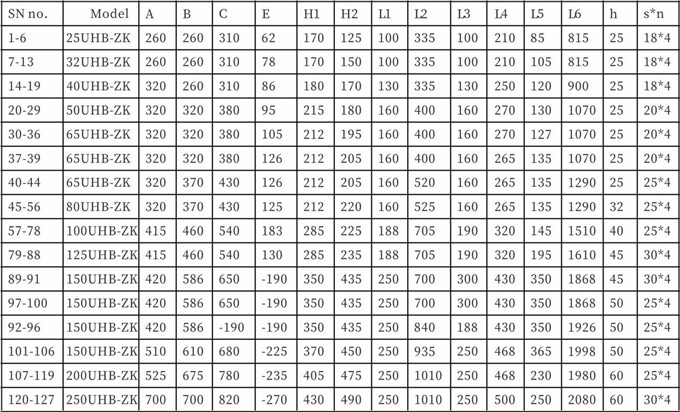

Outline and installation dimension Installation dimension table

Installation dimension table Flange connection dimension table

Flange connection dimension table

Reference standard:GB9116-88 PN1.0MPa

Remark:

1. For the pump with inlet ≥ 150mm, the outlet position of the pump is opposite to the figure.

2. The nominal pressure of the inlet flange of all series pumps in our factory is 1.0MPa. The standard code is: flange D-10GB9116-88, D is the nominal diameter.

3. Serial number: refers to the serial number listed in the performance parameter table at the front of this book.

4. The L6 listed in the table is the total length of the pump when equipped with a two stage motor. If equipped with a four stage motor,L6 will decrease with the decrease of the motor length.

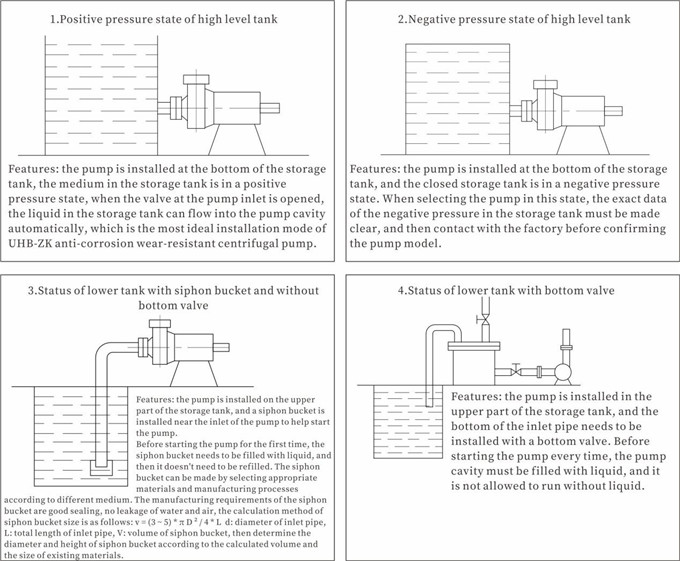

Installation diagram and description of UHB-ZK series pump under several common slot conditions  Main parts (accessories)

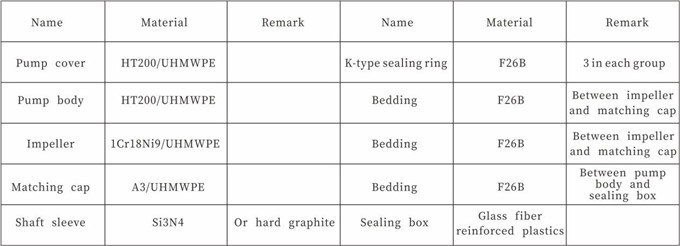

Main parts (accessories)